Process Overview

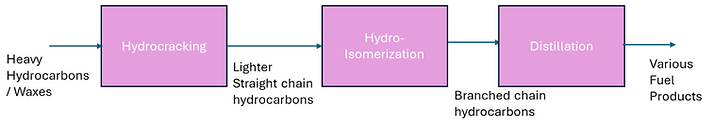

The Hydrocarbon Product Upgrading process is typically used to convert hydrocarbons from the Fisher-Tropsch process into high value added fuel products like gasoline, diesel and kerosene. Fischer-Tropsch process produces heavier hydrocarbons like waxes and long chain alkanes. In the first step, these heavier hydrocarbons are broken into lighter straight chain paraffins in the hydrocracking process using hydrogen. Next, the straight chain molecules are converted to branched chain hydrocarbon molecules in the hydroisomerization step. The branched molecules improve the properties such as octane number and cold flow of the fuel product. In the final step, the various hydrocarbon fractions are separated to yield the various fuel products such as LPG, naphtha, gasoline, diesel and kerosene (jet fuel).

Process Schematic

RVN advantage

RVN Technical Team has the expertise and experience to select the best available technology for the Hydrocarbon Product Upgrading process. We work with all licensors to evaluate which technology offering suits the client’s objectives best and works well within the project constraints. We also put together engineering designs for all process steps including the balance of plant equipment such as utilities, tank farm, unloading and loading. RVN can lead/support project execution from the conceptual design stage all the way to the detailed engineering stage. RVN works with partners that can provide procurement, construction and startup services. In short, RVN can help turn conceptual ideas into fully operational projects making commercially successful products in a safe and environmentally friendly process.